HERITAGE

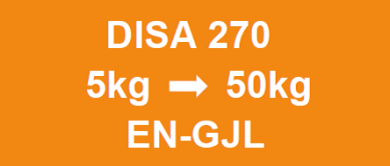

1982 : Installation of the Disamatic 270 automatic plant for vertical molding. Big production series of grey cast iron pieces up to 50kg each.

1994 : Investment in a hot blasting furnace for a reduced consumption of energy.

2008 : Acquisition of the first high speed machining center dedicated to the modeling workshop.

2010 : Mr Hugh AIKEN acquires the foundry.

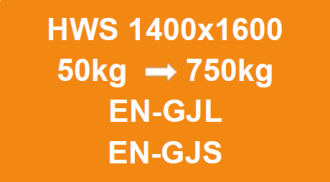

2012 : Installation of the HWS horizontal molding line with 1400x1600mm frames, (450+450)mm high, for pieces up to 750kg and short production series.

2013 : Fonderie de Niederbronn elarges its offer with ductile iron castings.

2014 : The foundry develops its skills (Cofrend 2 certifications - MPI, LPI and Ultrasonic Inspection) and enters some new markets (pumps, construction industry machines, railway).

2015 : International business development.

2016 : First major and international contract on the renewable energies market.