SERVICES

ENGINEERING DEPARTMENT

Our technicians work with SolidEdge, NX and Work NC for assisted Design.

Novacast is used for our simulations of casting solidification.

Our 3D measuring equipment is at disposal from sample scanning to 3D drawing.

> Exchange data with AEGIS (IGES), STEP, PARASOLID files

> Competitive solutions for 3D-prototyping

> Product definition

> Validation of initial samples

> Follow up of dimensioning changes and product updating

PATTERN SHOP

Several 3- and 5-axes machining centers are dedicated to our pattern shop for the shortest lead time of tooling and first samples

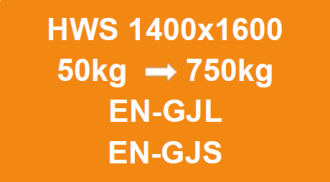

> Machining of patternplates 1400x1600mm large

> Machining of patterns up to 2x450mm high

> Machining of core boxes up to 100 liter

MACHINING, FINISH AND ASSEMBLY

> Shot-blasting, grinding

> 2 Johnford machining centers

> 1 Mazak machining center

> Painting line : coating or finishing

> Dedicated assembly and packaging lines